One of the life experiences that comes with being a three decade veteran of military procurement is you have been around long enough to know where all the important bodies are buried — case in point, the Boeing 737 MAX. What we are seeing in the two recent 737 MAX crashes is the the 20 year accumulation of professional toxic waste and decay in Boeing management that came with the first Clinton Administration’s cancellation of MIL-STD-499A SYSTEM ENGINEERING MANAGEMENT.

I was e-mailed a link today to this Daily Kos post on the 737 MAX :

Did Boeing ignore basic SW engineering principles?

Thursday March 21, 2019 · 8:34 AM CDT

and this passage just jumped out:

A few software engineering principles:

- Software engineering 101: validate your inputs.

- Software engineering 201: when something goes wrong, provide useful data to the human.

- Software engineering 301: for life-critical decisions, avoid single point of failure.

Until today, I had thought that aviation was *good* at software engineering. But my faith is shaken by the New York Times description today of what went wrong with the Boeing 737 MAX.

The above passes my professional “Bozo Test” of whether the poster knows what he is taking about regards software development. He does.

This is where that “military procurement life experience” I mentioned comes in. The timing of the development of the 737 MAX MCAS software was roughly 20 years after the Clinton Administration cancelled the majority of Mil-Specs in the mid-1990’s and in particular the one for system engineering management.

See:

MIL-STD-499A (NOTICE 1), MILITARY STANDARD: SYSTEM ENGINEERING MANAGEMENT (27 FEB 1995) [NO S/S DOCUMENT]., MIL-STD-499A (USAF), dated 1 May 1974, is hereby canceled without replacement.

The 1992 Politics of Mil-Spec Cancellations

That Mil-Spec cancellation was related to both then Defense Secretary Cheney’s cancellation of the stealthy A-12 Avenger 2 attack jet and the subsequent support that then “Candidate for President Clinton” got from major American defense contractors.

This support of Bill Clinton was retaliation by the big US defense contractors for Defense Secretary Cheney holding large defense contractors accountable for a major defense program’s failure to perform. Killing that political precedent was a vital interest for American defense contractors in the 1992 presidential election.

https://www.youtube.com/watch?v=w9B_VGvGVec

The 1995 MIL-STD-499A notice of cancellation means the Boeing management involved with the 737 MAX software development grew up professionally after after DoD directed system engineering management ended…and it shows. Again from the Daily Kos:

-

- There are two “angle of attack” sensors on the plane, but the software that controls the position of the nose of the aircraft relied on just one of them.

- A previous Seattle Times article had explained that the software then fought with the pilots, refusing to put the nose where they wanted it.

- Boeing sells an optional(!) indicator to tell the pilot what the angle of attack sensor is sensing.

- Boeing sells an option(!) to tell the pilots when the two sensors disagree with each other, a “disagree light”.

- And in the biggest “no sh*t sherlock” that I have ever read about software:

In the software update that Boeing says is coming soon, MCAS will be modified to take readings from both sensors. If there is a meaningful disagreement between the readings, MCAS will be disabled.

Gasp. How could the plane have been released without the two options, and without this check for disagreement?

Systems engineering Mil-Specs were the institutional basis that the US Defense Department used for “inculcating” systems engineering rigor into (Read: Force down the resisting throats of) large government contractor corporate bureaucracies like Boeing.

MIL-STD-499A didn’t always work in defense projects, but the formal structure of this systems engineering Mil-Spec left little room for the Dilbertian “pointy haired” management types to play the games you saw in the 737 MAX.

It also gave good engineers room to do their thing because the preparation process formal Mil-Spec reviews distracted the hell out of the pointy haired management types from dreaming up things like making passenger flight safety into a profit center.

The rigor of the MIL-STD-499A SYSTEM ENGINEERING MANAGEMENT approach trained good contractor program and production managers. These managers were systematically stolen from the defense side of Boeing into the commercial side for difficult developments because they had the skills set to juggle/coordinate a whole lot of organizational and sub-contractor balls at the same time. This was what MIL-STD-499A required to meet its performance metrics. Point in fact, many civil projects of the era used MIL-STD-499A when systems reliability really mattered.

My 737 MAX Investigation Expectations

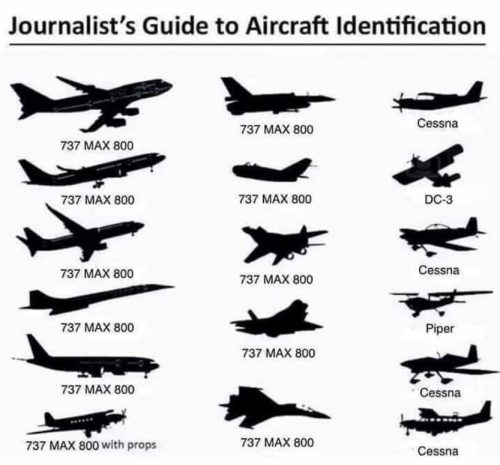

I don’t expect the main stream media to go anywhere near the information above both because of the “Narrative Implications” regards the Clinton Administration and for the very basic fact that the “credentialed but uneducated” 27 year old reporter with a journalism degree’s reporting on the 737 MAX has the following level of aviation technical skills:

I expect the MSM reporters will get used by everybody Boeing has screwed in the last 10 years and who wants pay back in exactly the same way that MSM reporters were used by both the Hillary for President Campaign and Comey era FBI with the “Trump-Russian Collaboration Conspiracy Theory.”

A Short Lesson in Systems & Reliability Engineering

This ignoring of the Mil-Spec cancellation connection to the 737 MAX is a shame. Since the basic practice of reliability engineering in hardware and systems is a very mature discipline. Basic mathematical reliability theory was solved during the 1950s. The best textbook every written on the subject is by Igor Bazovsky and was published in 1961. Bazovsky’s mathematical theories were codified in Mil-Hdbk-217, Mil-Std-756B and number of other systems engineering reliability standards. Bazovsky’s text book is both available as scanned PDF 1961 edition on multiple websites and as the 2004 hardcopy/Kindle edition ebook on Amazon here: https://www.amazon.com/Reliability-Theory-Practice-Mechanical-Engineering/dp/0486438678 .

Software reliability principles are also well understood, if lacking the strong theoretical foundation in systems and hardware modelling techniques that Bazovsky pioneered.

For an introductory understanding of how mathematical systems reliability models work with hardware and insights on the software/hardware interface, see the following systems engineering PDF document applying reliability formulas on the WW2 era P-38 Lightning fighters and several modern software/hardware systems failures:

System Reliability and Metrics of Reliability

Carlo Kopp

Peter Harding & Associates, Pty Ltd

Copyright 1996, PHA Pty Ltd, All rights reserved

http://users.monash.edu/~ckopp/SYSTEMS/Reliability-PHA.pdf

Summary & Closing:

These system reliability mathematics that apply to 737 MAX MCAS flight software & sensor hardware development are accessible to anybody with a STEM university education…but the life experience that tells me about where this particular body is buried also tells me mainstream media reporters will leave it buried.

-End-

The principles of reliability engineering are not specific to software: indeed, while MCAS was implemented as code, it could easily have been implemented as pure and fairly simple hardware…and, given the same specification, the same problems would have occurred.

Also, it should be noted that the dual-sensor requirement for MCAS triggering, now being implemented, does have a downside: if there is a *real* stall condition that requires MCAS action, then the failure of *either* angle of attack sensor will prevent that action from being triggered.

Intuitively, this still represents a considerable safety improvement from the current system: but the numbers should really be worked through in detail. I wonder if that is being done as part of the current project.

DAMN those Clintons!!

No. More like “Damn those defense contractors.”

Bill Clinton was rewarding supporters, as President, in the traditional manner.

A President keeping a campaign promise is our political system working as it should.

The Media hiding the bad results of keeping that promise, because they liked Pres. Clinton, is fundamentally corrupt.

I was an aeronautical engineer before medical school and have been interested for years in how to measure medical quality.

In 1978, the feds started what they called “Professional Standards Review Organizations,” or “PSRO” that were supposed to measure quality but it was quickly apparent. that All that they were interested was cost.

Nixon tried to push HMOs but people did not like them for the same reasons that prepaid plumbers are not that popular.

After my back surgery forced me to retire from doing surgery, I went to Dartmouth to learn some new methods using statistical methods to analyze care.

I thought I could have a new career sitting at a desk instead of bending over an operation. Actually, laparoscopic surgery prolonged my career by about 5 years because standing and looking at a TV screen was much easier on my back. Anyway, I thought that a second career measuring quality and advising people and insurance companies how to use things like Demming’s methods to improve care. You know what ? NOBODY was interested. All they care about is cost.

I could not even get approval for a study that might cut cost for treatment of elderly. I had the funding for the study but the university administrators killed the study. With no data, they decided it would be too expensive,

I’m not at all surprised to read this about Boeing. I should not have been surprised about the resistance to quality improvement studies. Amory Codman, the first surgeon to study quality was fired from the staff of the Mass General.

The amount of defense contractor consolidation that was allowed to happen after the Cold War ended was a disaster. It was good for procurement officers and execs from the few companies left, but bad bad bad for the country.

Someone could write a great book about the fiasco that was the recent tanker contract award, where Boeing was the on again, off again, on again winner, and it was drenched in corruption and politics from day one.

I’m at the uneducated but trying to learn level where this is concerned.

I had heard that people, at least in a certain area, were putting less emphasis on Systems Engineering. I then constructed a theory why.

Theory had two components. First that programming is as an engineering discipline not as mature as some of the other ones are. (I could be wrong about this. Programming definitely does not have all of the features I am used to seeing in other disciplines. On the other hand, perhaps the licensure process is pretty cosmetic as far as that is concerned.) Second is that working on software in a large bureaucracy should possibly make the Systems Engineering Vee process difficult. If ambiguous failure states in software mean that severe but subtle bugs aren’t caught at the lowest level, it might be a pain and a half to get things fixed when trying to integrate all the software at the highest level. Especially if the modules are in the hands of, and by contract to be fixed by, different contractors.

I was talking to somebody about this thinking yesterday. He asked about the 737 Max, and I told him I didn’t know enough about what was going on with that. May have been the truest thing I said, in hindsight.

After reading Trent’s post, I suspect that my theory may be badly flawed thinking.

Assuming that I am wrong in my thinking, is it the sort of flaw that can be easily corrected? Is a case of me needing to shut up and RTFM? Or is it so deeply flawed that I should stop trying to think about systems engineering and programming, and find some area where I won’t hurt people? (My internal censor is suggesting the last may be blowing things out of proportion. My inner editor is telling me I won’t ask anything if I start cutting, and I need to both ask for help, and rethink things when I’ve had more sleep.)

My automobile, a 2008 Toyota, has a traction control system that can override my input. When it senses a loss of traction (wheel slip), an amber warning lamp illuminates to inform me that my throttle input is being overridden by the vehicle. In an extreme slide, the lamp illuminates, a warning horn sounds, and the anti-lock brake system is actuated to give haptic feedback via the pedal.

It boggles the mind that a modern aircraft could ship without the level of design rigor present in decade-old road vehicles.

Unfortunately, someone relied on the 100,000 hour (or another large value) mean time between failure calculation for the angle attack sensor only to have 2 failures within months. To have no redundancy, check of the altitude reading or other critical inputs constitutes a criminal failure on the part of the software designers.

FYI, I just did a few text edits for technical clarity in the article based on e-mail feedback.

Herzo said —

>>To have no redundancy, check of the altitude reading or other critical inputs constitutes a criminal failure on the part of the software designers.

Too my nose, this has the stink of a manager/marketing guru in Boeing senior management.

Trent Telenko Says:

March 25th, 2019 at 7:36 am

Herzo said ””

>>To have no redundancy, check of the altitude reading or other critical inputs constitutes a criminal failure on the part of the software designers.

Too my nose, this has the stink of a manager/marketing guru in Boeing senior management.

I cannot disagree with your point, I have observed that the MBA is the worst thing that has happened to American business.

Still, your outline of the single point of failure tied in with the inability of the pilot to easily override the problem is a failure of the software designer.

It’s clear to me why the tilt control software was so messed up. It’s because they shouldn’t have had tilt control in the first place. The real problem was the monstrous engine upgrade causing the tilt problem.

Without the engine upgrade the planes are no longer economical. With the engine upgrade the planes are no longer safe. Boeing’s solution was to scramble to add a secret program to compensate for the problems with the engine.

This is indeed a system engineering problem, but it also confirms the old political adage that the coverup is worse than the crime. In this case, the software patch was worse than the problem it was patching.

Just about all large modern airplanes have electric trim, typically controlled by a switch on the control yoke or stick.

It seems possible that a plain, garden-variety electrical short could actuate an uncommanded trim action. This can be suppressed by using the switches on the center console. Manual trim via the trim wheel is always possible, and the wheel spins when electric trim is happening. From what I’ve read and been told, runaway trim is a standard simulator training procedure.

What’s different about MCAS is the way it trims, pauses, and then *trims again*. This must seem positively diabolical to those who ecounter it when they don’t know about the system OR don’t remember its existence quickly enough. Evidently, the simulators do *not* emulate this particular characteristic.

My automobile, a 2008 Toyota, has a traction control system that can override my input.

Remember, if you go to a conference on quality improvement methodology, even in healthcare, the model is Toyota. I have attended big national conferences in how to use Toyota methodology in health care.

What puzzles me is why Boeing could not just change the landing gear design and avoid the shift in center of effort in the engines so far forward, The Lockheed Constellation had very long landing gear.

There is a photo in that Wiki article showing they could put a cargo pod under the fuselage that still cleared the ground.

A couple of comments from a retired airline captain:

!. Lengthening the landing gear would have been the optimal solution, except that it would have required completely redesigning the center wing box, a major structural assembly, which is where the landing gear wells are located. Almost all the airplane’s major systems have at least some components which are located in, or pass through the center wing box. Such a redesign would have been extremely expensive, and probably would have triggered a complete recertification of the airplane. Boeing did redesign the nose gear, which gave them a few more inches of clearance for the engine nacelles. Nacelle ground clearance was the reason why the engines were moved forward of the wing, which led to the pitch up instability, which birthed MCAS.

2. My airline (a very large US major) has always (up to this point) declined to purchase Angle of Attack (AoA) gauges, even though they’d been available fo many years. the thinking was that the gauges themselves offer very little flight critical information that isn’t available from a simple airspeed indicator. The additional cost of the gauges is trivial, and was never a factor. All of our airplanes had AoA sensing systems, which fed data to stall warning systems, but not the gauges themselves. The stall warning systems would (very) rarely give false stall warnings, but not being connected to the flight controls, merely led to a few seconds of hair raising confusion. A TWA Lockheed L-1011 was totaled at JFK some years ago when a false stall warning on takeoff led to an ill-advised high speed abort and runway departure.

3. Despite all the well deserved mud being thrown at Boeing, I have to fault at least the Lionair pilots, it being too early to consider Ethiopian. The first rule of piloting is MAINTAIN AIRCRAFT CONTROL. This may seem obvious, but at some point the Lionair guys stopped making the airplane do what they needed it to do, and diverted their attention to trouble shooting, a fatal mistake. Even with MCAS trying to drag the nose down, they still had all the tools they needed to bring the flight to a safe conclusion. They had lost some flight instrumentation, but still had more than enough to get back safely. They trimmed against MCAS multiple times, then mysteriously, gave it up. The published accounts of the CVR tape indicate that they lost focus on aircraft control while trying to find the right checklist to run.

BobD…thanks for the comment. A question: I’ve read that even without an AoA indicator, the AoA data is used to display an AoA-derived lower-speed limit on the airspeed indicator. Is this correct?…if so, is it a standard feature or another option?

I agree the wing redesign would be more expensive but maybe not more expensive than this.

Agree about pilots and maintenance with Lion Air. The same airplane had the same problem the day before the crash, A dead heading pilot helped the crew turn off the MCAS.

Was this reported to maintenance ?

What was especially different about MCAS was that Boeing secretly added it without telling anyone because they were probably concerned that their engine upgrade dangerously changed the pitch.

A former Boeing executive, speaking on condition of anonymity because discussion of accident investigations is supposed to be closely held, said that Boeing engineers didn’t introduce the change to the flight-control system arbitrarily.

He said it was done primarily because the much bigger engines on the MAX changed the aerodynamics of the jet and shifted the conditions under which a stall could happen. That required further stall protection be implemented to certify the jet as safe…

“We had NO idea that this MCAS even existed. It was not mentioned in our manuals anywhere (until today). Everyone on the 737 had to go through differences training for the MAX and it was never mentioned there either,” the anonymous pilot posted. “I’ve been flying the MAX-8 a couple times per month for almost a year now, and I’m sitting here thinking, what the hell else don’t I know about this thing?”

I have been working on being less cynical in my old age, but I still have a hard time believing Boeing just committed an oops and forgot to tell the pilots about a system that was essential, not for fine adjustments to maintain smoother airspeed or compensate for fuel burn, but for preventing the new engines from flipping the nose up and crashing the plane.

Grurray…I’d be interested in learning whether the purchasing *airlines* were made aware of the MCAS.

If so, then one would think that being presumably sophisticated buyers, it would be reasonable that they would have been expected to order the AOA Disagree indicator feature.

If not, then of course they can’t be blamed on that score.

David Foster…That’s true for newer airplanes with all-flat panel flight instrument displays. The video display of indicated airspeed uses the AoA system to calculate minimum speeds for each flap setting, which appear on the indicated airspeed section of the display. No separate display of the actual angle value, unless the customer orders it. Indicated airspeed/mach is the metric for all other speed limits that I can think of, hence the company’s reluctance to add another instrument of limited utility. The airplanes I mostly flew (MD-80, Boeing 757/767) had mechanical airspeed gauges, and flap speeds were set using plastic memory “bugs”, which slid around the bezel of the gauge. The values of the flap speeds were derived either from charts or the aircraft Flight Management Computer, based on aircraft weight.

One of the first things I always tried to do when transitioning to a new airplane was to learn what “normal” looked like in terms of aircraft pitch attitude and power settings, for various phases of flight. For instance in the 757, normal cruise with the flaps up might be 2 degrees nose up on the attitude display, and throttles more or less straight up. Very rough, but knowing what it should look like makes it easy to spot false stall warnings or uncommanded autopilot action.

Best I can tell from brief discussions with my former compadres, they (including management) were totally ignorant of the existence of MCAS. The way it was wired up, AoA disagreement would be indicated by one pilot getting a stall warning(various flashing lights, computer generated voice yelling “STALL! STALL!” and a stick shaker) and the other pilot not getting these indications.

Bob D….thanks!

The 737 MAX crashes are not an issue of single point software failure.

It was a systemic failure of the commercial aviation certification, pilot selection, training and regulatory systems across the board.

The gist of the media reports too date include claims that:

1. The Maneuvering Characteristics Augmentation System (MCAS) system only employs at any one time one of the pair of redundant AOA sensors to detect an impending stall.

2. The system will not return to zero pitch input once the condition has been corrected, and continuously adds additional nose down pitch inputs until the elevators hit their stops.

3. Both the Lion Air and Ethiopian air crews were never trained on emergency procedures to disengage the MCAS in the event of problems.

4. Checklists did not include procedures to identify and isolate MCAS problems.

5. The MCAS has repeatedly misbehaved, but experienced crews were able to disable it, with the two accidents arising where crews were unable to improvise and disable the MCAS.

Capt Sullenberger of Hudson A320 fame has also weighed into the 737 MAX debate, criticizing a lack of proper pilot training, as well as the FAA’s failed certification process.

In short, both the Lion Air and Ethiopia crashes involved a multitude of items, man and machine, that were not working as intended at the same time. This is the typical failure template for commercial crashes.

What is atypical here is how the FAA regulatory and Boeing training system failed to recognize the generation shift in technology the 737 Max represented. (The US trial litigation system will be hashing this out for years.)

MCAS and the much larger CFM-56 Leap engines and nacelles on the 737 MAX airframe are a generational shift in commercial aircraft technology not unlike that of the Airbus A310.

The A320 was the first fly-by-wire airliner with a force sensitive sidestick controller. Unlike traditional controls, the Airbus scheme works differently, as your stick inputs set the aircraft’s pitch and roll attitude, which is held by the digital flight control system (DFCS) until you apply an opposite stick input.

This was not natural to pilots 25 years ago when the A310 was introduced. Airlines had to carefully pick pilots for A320 conversion, as only the best pilots were able to handle this system, especially under pressure. Less than outstanding pilots would often revert to habits gained flying traditional aircraft and mishandle the A320 under pressure.

This is what a pilot I know said regards his experience in the A310 simulator and the difference between digital and direct flight controls:

“I got an interesting demonstration during the demo flight – I was able to handle the simulator reasonably well, and did several clean touch and go circuits, but did need some help with managing the throttles to keep on the glideslope. My far more experienced fully instrument rated General Aviation instructor, whom I invited along, managed to crash the jet twice on landing, as she reverted to traditional control handing during short finals.”

Digital flight controls whether emulating conventional flight controls, or done the Airbus way, do need different training regimes, and not every pilot will cope.

Capt Sullenberger’s complaints about pilot training for the 737 MAX are spot on here.

When a “smart system” gets confused due to a sensor malfunction, you need a very quick and smart pilot to deal with the problem successfully. That comes of high quality training and proper candidate selection, AKA based strictly on demonstrated aptitude and not family connections or race/gender quotas.

Compare what happened with the Ethiopian and Lion Air crashes to the Airbus A310 crew hit by a shoulder fired missile over Baghdad — who were able to improvise and eventually land a crippled and barely controllable aircraft — or Capt Sullenberger’s outstanding Hudson river ditching.

The less adept crew simply were unable to deal with the 737 MAX hardware/systems/software problem and lost their aircraft.

We are seeing an increasing frequency of avoidable accidents arising from aircrew being unable to deal with complicated automated system misbehaviors and failures because aviation “Standard Practices” predating the digital age are clearly no longer working.

The digital flight controls and cockpit automation are not going to disappear, as airlines ($$$) and environmentalists (CO2) love the gains in fuel efficiency that engines like the CFM-56 Leap represent.

Recalibrating and revising aviation practices to accommodate this technology, from design, through test and certification, to training is required.

The two recent 737 MAX crashes show that the assumptions underlying these “Standard Practices” no longer hold.

Trent Telenko:

In short, both the Lion Air and Ethiopia crashes involved a multitude of items, man and machine, that were not working as intended at the same time. This is the typical failure template for commercial crashes.

It’s the typical failure template for modern complex systems of many kinds. In general such systems are optimized for efficiency at the cost of increased complexity and vulnerability to rare chance combinations of unfavorable events. This is the crux of Wretchard’s design margin and Nassim Taleb’s fragility arguments. Perfect storms happen occasionally and at frequencies that are difficult to predict regardless of everyone’s best efforts. It is therefore important for system designers to seek to minimize harm in the event of major system failures no matter how rare.

Trent…

Completely agree with your last comment, with a few quibbles:

1. Please don’t conflate the Airbus A310 with the A320. Completely different airplanes, with completely different flight control systems. The A310 is a non-FBW wide body.

2.The guys in the DHL Baghdad incident were hit by a surface to air missile , completely disabling all their flight controls. They successfully landed the A310 using only engines for pitch and heading control. Magnificent piloting indeed.

3. The underlying problem with MCAS, as I see it, is that it was only active at a time when the pilots thought that they had complete manual authority over the flight controls. It operated in the background, countermanding the pilot inputs, with no indication that it was running, and no hint from Boeing that it even existed. Confusion over who is flying the airplane has been a factor in many accidents, perhaps most famously, Air France 447. There are indications that a struggle over the controls was a factor in the recent crash of the Atlas Air 767 freighter on Houston last month.

4. I emphatically agree that we need to rethink our approach to the aircrew/automation interface. It needs to be much more transparent and intuitive.

Related to this thread: my post When Humans and Robots Communicate, also Automation, Aviation, and Business, with further links.

Derp…

…you’re right, I did conflate the Airbus A310 with the A320.

Mea culpa.

thank you. and thank you again. this all needs to be published many times over in the mainstream. and then on repeat in the industry.

Via Aviation Week —

Boeing: MAX Changes Add Redundancy, Pilot Control

Guy Norris | Aviation Daily

Key changes to the Boeing 737 MAX’s MCAS will incorporate more redundancy into the aircraft’s much-scrutinized flight-control law giving pilots ultimate elevator authority by limiting the degree of nose-down stabilizer command which the automated system can trigger, the company confirmed

Vipez Sez –

>>thank you. and thank you again. this all needs to be published many times over in the mainstream. and then on repeat in the industry.

The corporate bigs won’t listen and the FAA is too far down the path of the “Trust the Contractor Death Spiral” that happens via eliminating Federal civil service quality staff as a cost cutting move, which leaves the regulatory agency a puppet for the contractors.

The key thing about the “Trust the Contractor Death Spiral” is when the contractors are bad and the regulatory agency needs to add back quality folks to reestablish necessary safety oversight. The Government regulators senior management cannot ask for it.

This is because the Congress is busy boondoggling the reduced oversight budget elsewhere and don’t want the contractors campaign contribution income reduced. So if asked for, the quality staff is not added and regulatory agency budgets are cut because you ticked off the Congressional Committee chairman.

So the regulatory agency senior management, knowing that is the outcome, tells the quality folks under them to stop rocking the boat and pretends nothing will happen and then kicks the can down the road.

The 737 MAX MCAS crashes are the logical ultimate outcome of the “Trust the Contractor Death Spiral.”

Boeing has released the description of their proposed changes:

http://www.boeing.com/commercial/737max/737-max-software-updates.page

…still needs approval by the FAA and other national airworthiness authorities.

Positively nailed it. Confirmed and applauded by folks who worked Avionics and Flight Controls systems test in the 2-122 building at Boeing Field.

On the other hand I would quibble ever so slightly with “3. Both the Lion Air and Ethiopian air crews were never trained on emergency procedures to disengage the MCAS in the event of problems.” The statement is correct that the two crews and many others were never trained specifically to diagnose and then disengage the MCAS.

The two crews and many others were trained for all models of the 737 first to last to forget specifics, forget diagnose, disengage all the automatic and pilot aids which includes but is not limited to the MCAS and fly the airplane including manual trim. Put the passengers in their seats and manual trim may be easier.

I would analogize to the folks who say don’t diagnose a jam in a gun fight. Try tap rack if bang continue if no bang reload. Diagnose if you survive.

On the other hand the 1996 Croatia USAF CT-43 (737 base) crash say might have been averted with Airbus style automation deploying high lift help for the climb out on this controlled flight into terrain accident.

This universal solution underlies the Boeing assertion that the 737-8 could be flown without additional training by anybody who knew enough and was disciplined enough to fly the airplane with artificial aids turned off and the willingness to do so. Might even have been right but it was not the traditional Boeing way.

Mr. Myers

Regards this —

>>This universal solution underlies the Boeing assertion that the 737-8 could be flown without additional training by anybody who knew enough and was disciplined enough to fly the airplane with artificial aids turned off and the willingness to do so. Might even have been right but it was not the traditional Boeing way.

The 737 MAX uses a conventional flight control system that seems directly derived from the original 737 NG system.

The MCAS system, based on what I have read, was piggybacked on top of the 737 NG’s classic mechanical flight controls and stick shaker system. And MCAS seems to be embedded as a software function in the digital autopilot.

This implementation has the “Look and Feel” of that Senior Boeing Marketing guy’s MCAS involvement I spoke to in an earlier comment.

The big Boeing marketing campaign selling point with the 737 MAX 800 was it required -NO ADDITIONAL- 737 air crew training for the additional profit making capability the CFM-56 Leap engine.

Because that was the key selling point. The Boeing 737 MAX 800 manuals didn’t have the “How to turn off the malfunctioning MCAS” instructions and the FAA was not clued in.

My gut says the original design goal of MCAS and everything that came after was an output from a Boeing senior management & Marketing President driven brainstorming session.

That is, the marketing goal was no additional air crew training life cycle costs for implementing the CFM-56 Leap engine on the 737 MAX 800, with flight safety being a very distant third.

I was just e-mailed the following.

It seems my thoughts regards the MCAS being designed to make the 737 MAX 800 fly exactly like the 737 NG has been confirmed —

https://aviationweek.com/commercial-aviation/boeing-adds-redundancy-and-more-pilot-control-737-max

Boeing stresses that it began developing the MCAS enhancement package over the past three months after issues with flight-control software, systems and pilot training were implicated in the crash of the Lion Air 737-8 in October. The enhancements were therefore already in development when the MAX suffered its second loss with the crash of Ethiopian Airlines Flight 302 (ET302) under similar circumstances on March 10.

As well as helping the MAX to handle like the 737NG, the MCAS was introduced to decrease pitch-up tendency at elevated AOA. The changes in handling, which were found during testing in an extreme part of the flight envelope, were caused by the additional lift generated by the nacelles of the MAX’s larger CFM Leap 1B engines, which are located farther forward than on earlier 737 models.

The first change, “and probably the most important,” Sinnett says, “is that we compare data from left and right AOA sensors full time and when the flaps are up””in a situation when MCAS would be armed. If they vary by more than 5.5 deg., the system will inhibit MCAS and the entire speed trim system for the remainder of that flight.” If an AOA disagree of more than 10 deg. occurs between the sensors for more than 10 sec., it will be flagged to the crew on the primary flight display.

“In addition, as a customer option, we provide the optional capability to display raw data for AOA,” Sinnett adds. “Most airlines do not select this because it is purely supplemental information. None of Boeing’s current training or procedures require AOA information.”

In the current MAX design, the MCAS receives input from only one sensor during each flight. The left and right sensors alternate between flights, feeding AOA data to the flight-control computer and the MCAS. The single-point-failure potential of the original design was criticized in the wake of the Lion Air accident, where erroneous data appeared to trigger an MCAS activation.

Boeing also confirms that the system will allow only one trim application for each new trigger of the MCAS system by an elevated AOA event. The revision means the MCAS can never command more stabilizer input than could be countered by the crew pulling back on the control column. The company says its failure analysis of the system indicates there are no known or envisioned failure conditions in which the MCAS will provide multiple inputs.

Under the original design, the MCAS trims nose down up to 2.5 deg. by moving the horizontal stabilizer at 0.27 deg./sec. for 9.2 sec., stops for 5 sec., then trims nose down again for 9.2 sec. and continues to do so until the trim reaches the stabilizer travel limit or the crew intervenes. Boeing reemphasizes that the crew will retain the capability to override the flight-control law using electric trim or manual trim, or by following the existing runaway stabilizer procedure and using the cut-out switches, as reinforced in the Operations Manual Bulletin issued on Nov. 6, 2018.

The third major change is that “there is no situation in which more stabilizer input can be provided by MCAS than there is control column authority for pilot response,” Sinnett says. “The control column will always be able to override MCAS inputs. These are very important changes.”

Changes to the training program include an updated level-B computer-based training program to enhance pilot understanding of the 737 MAX speed trim system, including the MCAS function and the associated crew procedures and software changes. Alterations are also planned for the Airplane Flight Manual and Flight Crew Operations Manual as well as new notes for the speed trim fail checklist in the Quick Reference Handbook. Other changes are being made to the Airplane Maintenance Manual and the Interactive Fault Isolation Manual.

“We are working with customers and regulators around the world to restore faith in our industry and also to reaffirm our commitment to safety, and earning the trust of the flying public,” Sinnett says

Boeing and the FAA committed three unbelievable, unforgivable mistakes.

First: Making a major change in the way the plane operated and deliberately withholding that information from the pilots.

Second: An incredibly stupid, simple minded design. A commenter on Rand Simberg’s likened it to what a kid would try with an Arduino. The kid would quickly find out why it was a bad idea. 2,B: Choosing to initiate it when the flaps are retracted guarantees that the malfunctions occurred close to the ground at relatively low air speed while the pilots were already busy.

Third: The trim is capable of completely overpowering the flight controls. Mitigating this are instances where trim controls were used to control and land planes after the main flight controls were disabled for some reason. Until now, this doesn’t seem to have caused crashes. It took combining this with an automagic control to make it a killer.

This is just the latest of a decade of Boeing screw ups that started with the delays and overruns on the 787, numerous problems with the KC-46, the Orion capsule and finally this. Lockheed survived the Electra barely, the Comet killed De Havilland. Not withstanding that both eventually became successful aircraft. In justice, everybody at Boeing, VP and above, should be investigating career opportunities in the Hospitality industry, but even Starbucks is downsizing.

MCS Said:

>>>In justice, everybody at Boeing, VP and above, should be investigating career opportunities in the Hospitality industry, but even Starbucks is downsizing.

True, but I fear Lockheed-Martin is no better — see the F-35.

The USA does not have the systems engineering to be capable of producing the top of the world class airframes any longer.

The arrival of fighter ace class AI pilot software. Plus the demonstrated loss of systems engineering skill in the major US aerospace contractors. Means that places like Israel — who learned real top end system engineering skills with the cancelled for money and political engine source reasons LAVI fighter — are set to take over the future multi-role fighter class UAV market.

The rise of China means Israel has an alternate source of electronics and engines for such a weapons system and the near term arrival of Israel as a energy exporting power means is will soon not need American FMS budgetary assistance.

I don’t believe the problem is a lack of technical competence. I think major US defense contractors are fat and lazy due to lack of competition. You’ve got mid and senior leadership now who came of age way after the post-Cold War consolidation, and during the post-9/11 funding boom. They haven’t ever had to really focus on producing excellence.

I was working at Douglas Aircraft when the F 5 D plane was completed. The chief engineer met with the division VP and was told the plane had been cancelled as the Navy liked the predecessor, the F 4 D, and did not want the new plane. Notwithstanding it was far better and the F 4D have been developmental.

The chief engineer shot himself in the VP office.

The Douglas F5D Skylancer is a development of the F4D Skyray jet fighter for the United States Navy. Starting out as the F4D-2N, an all-weather version of the Skyray, the design was soon modified to take full advantage of the extra thrust of the Pratt & Whitney J57 eventually fitted to the Skyray instead of the Westinghouse J40 originally planned.

The first flight was on 21 April 1956 and was supersonic; the aircraft proved easy to handle and performed well. After four aircraft had been constructed, however, the Navy cancelled its order. The stated reason was that the aircraft was too similar to the already-ordered Vought F8U Crusader, but it is believed by some historians that politics played as big a part; Douglas was already building a very large proportion of the Navy’s planes, and giving them the F5D contract would have made it even closer to monopoly.

Douglas was out of business in a few years.

Brian,

Living with large US Defense contractors is part of my day job.

Three decades of looking at elite leadership infected with arrogance, ignorance and a feeling of entitlement has shown me that can’t be fixed.

It can only be replaced.

The issue regards the Boeing 737 MAX 800 is that were are talking both the FAA as well as Boeing with the arrogance, ignorance and a feeling of entitlement problem.

The scarier issue with the F-35 is that it involves the Congress and Defense Department as well as Lockheed Martin.

The USA today facing a rising China is very much in the position of the French Republic prior to WW2 facing Germany.

Unlike France, our economy remains bigger than China’s for the next couple of decades. And we have both the Pacific Ocean and nuclear weapons that France did not.

But all golden ages come to an end.

I don’t think that our economy, nukes and the Pacific Ocean are enough with the American elites we currently have. Who seem to be bound and determined to have a civil war to feed this virtue signaling PC fantasies.

Trent: I don’t think we’re disagreeing. I’ve also seen from the inside how dysfunctional defense contracting is for the past few decades. It can seem kind of amazing that we win wars, given how bass-ackwards things often are. The blame should go to the bureaucracy, and the lack of accountability, which comes from no competition. As I said a week ago: “It [post-Cold War consolidation] was good for procurement officers and execs from the few companies left, but bad bad bad for the country.” The only way to change it at this point would be for defeat to make it clear to everyone that things have to change. Which to me makes it unlikely things will change, as I don’t see China as actually being a peer-competitor existential threat–they’re even more inbred, of course, and their capabilities on all fronts are nothing but a fraud. I think our likely future lies in cultural differences and hatreds spinning the country apart, not in defeat by an external military force. (Also, anyone who knows anything about the US military knows we’ll never be a military dictatorship, because the military culture is for the average grunt to hold the officer corps with barely concealed contempt.)

MCS…”Choosing to initiate it when the flaps are retracted guarantees that the malfunctions occurred close to the ground at relatively low air speed while the pilots were already busy.”

Actually, flaps are generally used WHEN the airplane is close to the ground at a relatively low airspeed. They change the aerodynamic characteristics of the wing to reduce the stall speed so you can land without a 5-mile-long runway.

All large and most non-large airplanes use flaps for landing; many also employ flaps or partial flaps for takeoff. There would be no reason to employ flaps during cruise flight; indeed, there is generally a flaps-maximum-extended speed in the aircraft Limitations.

Brian,

America can lose.

China and it’s leaders does not have to be a great. China and its leaders only has to be better than our elites.

Look at the decay of Chicago’s civic mores and specifically the relationship between the Chicago Police Department and Chicago elites in the Jussie Smollett affair. The CPD is being forcibly devolving into a armed support group for the strongest political faction in the city.

Now imagine a Rural-Urban US Civil War a decade or two from now where rural forces cut off Chicago from the electric grid for weeks.

What do you think will happen in Chicago? Or the Boston-Washington urban corridor?

My guess is that it will all be Venezuela without electric power writ large.

And how will China be able to take advantage of that?

China — my guess is that Airbus will effectively be a Chinese company within a decade. Think how fast the Chinese have built their industrial base in steel, ship-building, automobiles, electronics, space. Aviation is clearly on their menu.

I recently returned from a short project in Western China, my first exposure to the country. In certain ways, China seems more American than America has become. Just on the airline front, no less than 17 (!) Chinese airlines with Airbuses & Boeings were competing for business at one of the airports I used. While California has spent billions of dollars on lawyers talking about high speed rail, China has actually built impressive rail systems across the country — clean comfortable 150 mph trains barreling through 25 mile long tunnels. Wow! And while the necessary technology may have come from outside China, the Chinese made sure to build the trains in their own country and develop their industrial base. Generally, Chinese infrastructure is stunning — innumerable modern bridges over the Yangtse river; Dubai-standard airports; metro systems that Paris or London would envy, in cities most of us have never heard of; monorails in Chongqing, maglevs in Shanghai; staggering tourist facilities.

Thinking about life for the Chinese guys I met — they can find a job, or start their own business; they can buy their own home; buy a car or SUV, drive it on impressive urban freeways or excellent inter-city toll roads; invest in stocks & bonds; shop at Walmart or Prada, in innumerable business districts with entertaining pedestrian precincts; choose schools for their children, and medical services for themselves; travel internally and internationally with minimal restrictions; all amid a general feeling of personal safety, with only a modest (generally unarmed) police presence. It surely is not Lenin’s Communism!

Big difference I see between China and the US now is ”¦ Competence. The US had competence in government & industry up to the 1970s, but has now lost it in too many areas. Chinese leadership today has competence. Of course, China has its own problems, and future generations of Chinese political & industrial leaders will likely suffer from the same degradation of competence that we face in the US. But for now, we need to take China very seriously.

Gavin…”China has actually built impressive rail systems across the country ”” clean comfortable 150 mph trains barreling through 25 mile long tunnels.”

Yet, I wonder how many of these impressive infrastructure projects represent an appropriate use of investment capital vs being politically-motivated. Haven’t heard much about the “ghost cities” in recent years–have theybecome any less ghostly? And specifically regarding rail: one (very brave) Chinese railroad expert said that way too much funding is going to the prestige HSR projects as opposed to workaday freight rail. (I believe he even said something about ‘political leaders playing with train sets’)

In any event, we do need to be taking China very seriously, and the hysteria about The Russians has detracted from that.

Also…”It surely is not Lenin’s Communism!”

Indeed, calling the place ‘Red China’ is pretty silly. The Chinese government probably does it to gain the authority of historical continuity….surely, *they* don’t really think they are following Marxism-Leninism.

China today seems to have a considerable resemblance to Kaiser Bill’s Germany, with more competent (and hopefully more stable) leadership.

Gavin: Hrm. I haven’t ever been to China, but I did know a man from China who was terrified that he might have to go back, because he and his wife had had a second child while in America. And he was from a small rural town that had been basically forcibly depopulated by the authorities. I don’t think your claims about the freedoms that the average Chinese citizen enjoys are at all accurate.

I’m not saying we should disregard China, but I don’t think we need to fear their military, because it’s basically a fraud like all communist institutions, and making hostilities overt would destroy their economy, which is based on hoovering up money from international corporations who want to use the command economy to make more efficient manufacturing systems. That’s not a sustainable plan, and their one-child policy means their demographics preclude them from actually achieving global superpower status.

David — Like any short-time visitor, I got only a keyhole look at China. I am certainly not an expert on China; all I can say is I was impressed by what I saw. In the US, the Political Class have run up a lot of government debt handing out money to various groups of idle people for current consumption — the Chinese Political Class has run up debt building infrastructure which is being heavily used. It is obvious which was the smarter move.

In the areas I saw, there is a lot of construction going on – apartment blocks, roads, industrial parks. I wonder if the “ghost cities” are basically similar to what the British did post-WWII with their “new towns”, where they built infrastructure, housing, relocated factories to move people out of over-crowded cities? Since they build the housing before the local jobs are created, there must be a period of under-occupancy.

Rail — I saw very little signs of freight movement by rail. That may be similar to Europe, where Eurotrash talk smugly about how much better their passenger rail systems are than the US while they have nothing similar to those mile-long freight trains thundering across Texas. I have heard that it is very difficult because of scheduling to run freight and passenger service on the same rails — in any country. The high speed passenger trains I took were mostly a 16-coach design, with about 80 passengers per coach; assigned seating; and mostly nearly full — very efficiently run. Train stations were airport-standard, and very busy. The various metro systems were heavily used, and the freeways were mostly very busy. The infrastructure is not vanity projects — it is being used.

I haven’t been to China either but deal with Chinese suppliers all the time via videoconferencing, skype, email, etc. They are mostly conscientious and agreeable. They hit deadlines without fail, and they don’t mind cutting corners to do it. Quality is a constant worry.

My question is always, can you drink the water out of the tap? That’s my benchmark.

Now imagine a Rural-Urban US Civil War a decade or two from now where rural forces cut off Chicago from the electric grid for weeks.

A few years ago they closed the last coal plant within the city limits. It was built in the 20s on the South Side. They closed it in the name of environmental justice.

The plan is to turn it into a distribution center for Amazon or Fed Ex. A lot of good that will do if the transmission towers outside of town are toppled and the power lines cut.

Brian — I am simply trying to convey what I saw in China, where people seem to have many of the same freedoms we have. I have no idea how typical the Chinese people I met and worked with are — but they were very welcoming, inviting me into their homes (which they owned), driving me places in their cars; they put a lot of effort into choosing (and paying for) schools for their children, and they moaned about declining stock prices.

The one-child policy is gone, as is obvious from seeing families in the pedestrian precincts with two or more children. We all know to be cautious about government statistics — our own government’s, as well as the Chinese government’s. I do wonder about the statistics that China has a surfeit of young males because of sex-selective abortion. The impression in the cities I visited was the reverse — there seemed to be a near-endless parade of slim young women with long dark hair and a pleasing absence of body piercings and tattoos. Many jobs that elsewhere might be done by young men (e.g., street-cleaning, policing, security) are done by women. Maybe large numbers of young men have been shipped off to remote construction sites or recruited into the military? — but I saw no evidence in the cities of excess males.

As far as being concerned about China — remember Sun Tsu’s view that the real Art of War is to win without fighting. China can make almost everything it needs, while we in the US are now heavily dependent on imported Chinese manufactures. All China wants from the outside world is resources, and all it needs is for the US to stay out of its way, which the Chinese can largely accomplish by buying US politicians (and if necessary by threatening to withhold exports).

My guess — At some point, China will take Taiwan, and a Democrat Congress will issue a proclamation congratulating China on its reunification. Japan, Korea, Vietnam, Philippines, Australia will realize they don’t have the US to back them up, and will decide that cutting deals with China is better than losing an unequal war.

Personal view — the smartest policy the US could follow is to rebuild our manufacturing & research capabilities (probably a 20-year project) — but our Political Class lacks the vision, drive, and competence to accomplish that. Advantage China, I am sad to say.

“can you drink the water out of the tap?”

I did — with no apparent ill-effects. Often in eating places, they would provide boiled water from kettles, but that seemed to be more of a cultural preference for hot water than a water quality concern. Lots of bottled water, of course — just like France or New York City. And it must be noted that the water makes very fine beer!

Gavin,

The 800-lb gorilla in the US vs China competition is called corruption.

The Chinese have a great deal more corruption in their basic life support and they have exported the consequences of it to Latin America and the USA.

See this —

http://www.time.com/time/printout/0,8816,1638436,00.html

Thursday, Jun. 28, 2007

The Growing Dangers of the China Trade

By Jyoti Thottam

On a warm Friday afternoon in June, about 50,000 boxes of toothpaste got their last squeeze inside an industrial trash compactor in Homestead, Fla. They were yanked from the shelves of discount stores and bathroom cabinets after a nationwide recall warned that the toothpaste contained a chemical, diethylene glycol, that could lead to kidney failure. Francisco Botta, who distributed the toothpaste for his family’s wholesale business in Miami, stocked his warehouse bathroom with the stuff. “I used it every day,” he says. “I told everybody to stop.”

Like so many other things that Americans buy these days without thinking, those tubes of Dr. Cool, Superdent and Everfresh Smile2 began their life in a factory in China –in this case, in Wuxi, a city of 4.5 million about 80 miles west of Shanghai. They were sold by Goldcredit International Enterprises, which is based in a gated community called Lakebank Elegant Garden, within sight of China’s Taihu Lake. It makes not just toothpaste but also pencil sharpeners and balloons, hand sanitizer and toothbrushes. “What we exported is in line with the Chinese-government standards,” Goldcredit business manager Shi Jun says about the toothpaste. Adds manager Hu Keyu: “The Chinese government already issued a statement. What more do you want from us?”

Would a nontoxic dentifrice be asking too much? On the 8,000-mile journey between Wuxi and Homestead, Goldcredit’s products move, in effect, through time. When a product made in China enters the U.S., it arrives with a kind of unfettered capitalism that hasn’t existed in America for a century–uninhibited by regulation, lawsuits or, until recently, public outrage. It’s difficult even for a businessman who tries to follow the rules. “You go to China, you check the place out, check the quality of the products,” Botta says. But after the recall–of a product labeled safe in China–he is wary. He saw a big candy factory while he was in Wuxi. “I wouldn’t buy that,” he says. But he’ll continue importing school supplies and shower curtains.

It’s the same calculation that millions of American consumers are making since the recent recalls of deadly pet food, lead-paint-tainted toy trains and shredding tires made in China. The U.S. imported 40% of its consumer goods from China last year. But there is no practical way to gauge, other than by reputation, whether a Chinese import is as safe as it is cheap. So should you worry more about the extension cords or the TV? Screen the kids’ toys but not their shoes? Until China’s capitalism develops its own set of rules and limits, is that our only option in a made-in-China world?

Every time a federal agency recalls a Chinese product–as the National Highway Traffic Safety Administration ordered June 26 with nearly 450,000 tires–consumers get jolted with concern but also relief that someone is paying attention. Yet the volume of imports from China is straining the capacity of U.S. regulators to watch them, and those goods are overwhelming China’s efforts to reform the eight disparate agencies that regulate its consumer products.

More than 40% of recalls by the U.S. Consumer Product Safety Commission, including all the toys recalled this year and 79% of toys last year, involved products from China. The volume of consumer goods from China has nearly tripled since 1997, but the agency’s budget has increased just 12%, to $62 million, over the past five years. “There’s no question it’s strapped,” says Eric Rubel, a former general counsel to the commission.

>SNIP<

Gavin,

The ultimate product of any industrial process in an authoritarian/totalitarian political system is toxic waste.

You cannot root out corruption in authoritarian/totalitarian political systems because it always devolves down the lowest level due to the lack of checks and balances of a representative government.

The Stalinist terror in Russia was required to keep corruption centralized cannot be sustained over the long term.

China is on the same “political corruption failure trajectory” as the Soviet Union. They are just taking longer thanks to outside infusions of capitalism.

Consider the implications of that toxic waste corruption for Chinese goods in the world economy in light of these two comments on that 2007 article above I got from one of my e-mail lists:

—

Correspondent A –

>You also assume that the goods inspected in China by outside inspector are the ones exported.

>Absent counterfeit-proof serial numbers, a corrupt government (one whose officials are corrupt and can’t be purged) can overcome any QA process in their jurisdiction.

Correspondent B –

A guy I know (coincidentally enough, he’s also named “T”) works for a sugar company; he’s basically the highest-level QA official for the company’s organic sugars.

(One would think nothing could be more organic than pure cane sugar, but one would be wrong. The cane can’t have come in contact with chemical fertilizers or pesticides, for one thing. For another, one stage of the crystallization process requires an infusion of ethanol, so to obtain organic certification, the ethanol must also have been derived from organically grown crops. For a third, no piece of equipment that actually touches the sugar can ever have met inorganic cleaners, solvents, or what have you. For a fourth, no chemical pesticides or rodenticides can be used in the plant.)

(Apparently roach legs and rat turds are acceptable, as they’re organic.)

The company has its own farms (plantations?) in the US and Canada (sugar beet farms, in the latter case); it also buys from foreign producers. One of its larger contract producers is in South America (Brazil, IIRC).

“T” has spent a lot of time at that plant, because South Americans have been known to be, well, a little lax about enforcing truly organic procedures.

The plant’s in the middle of many, many acres of sugar cane. It uses most of the cane for sugar, and some for ethanol. The fields are double-fenced, with native vegetation between the fences, so that pesticides can’t drift in from adjacent farms. Access is strictly limited, so that nobody can accidentally carry in something that might ruin an entire production run; an international security firm provides dozens of round-the-clock guards to maintain that limited access. When the sugar is finished, it goes into organically-acceptable bins, which are then loaded onto a huge container for ocean transport. When the container is full, Brazilian and US customs officials inspect it, approve it, and seal it. Armed guards escort it to the port, and watch until it’s been safely stowed on the container ship.

Last year, “T” got a bit perturbed. A container had arrived at the company’s repackaging and distribution center in Louisiana. All the locks and seals were intact, and showed no signs of tampering. Yet the container was filled with bricks instead of sugar.

He still doesn’t know how it happened, but does take some solace in the fact that at least it wasn’t filled with inorganic sugar….

—

Consider for a moment that in today’s “free trade” environment that Ford is losing $1 billion a year in sales to counterfeit “brand name” autoparts from China.

What happens when the American people react to toxic Chinese goods with consumer boycotts of retailers who market them?

The modern container cargo system is the ultimate aide to counterfeit shipments. Unless cargo containers are inspected 100% by non-corrupt inspectors outside China, with 100% control of the supply chain from that “known good” point to the American market, toxic goods will get through.

Even then, importation of toxic Chinese goods via brand name & other substitution via 3rd parties in Latin America and elsewhere will spawn a very nasty American legal environment. One that will make anyone in a market distribution supply chain legally liable for the effects of toxic goods the way anyone in the chain of ownership of a Superfund Toxic waste site is.

Yet that will be the only way to keep the American people from economic autarky in self defense.

Gavin,

The Chinese Communist Party is the ultimate destructive force of the Chinese “National Brand” because the power agendas of their govt ultimately clash with the agendas of the Chinese economy.

Please see here:

2008 Chinese milk scandal – Wikipedia

https://en.wikipedia.org/wiki/2008_Chinese_milk_scandal

In reaction to the CCP investigation and execution of the top people involved with the toxic milk formula scandal. China has become the world’s biggest importer of Aussie dairy product, especially baby formula. IOW, when it comes to the Chinese public’s trust of domestically made baby formula.

The CCP’s corruption has destroyed the “Chinese brand” at home.

Admittedly the issue of American elites destroying the interests of the American economy for the power interests in D.C. are a major problem in America.

However, the US federal governmental structure and independent – if increasingly Leftist judiciary – removed politics from food alteration scandals, allows things like oil/natural gas frac’ing to get going and marginally “Elite Outsiders” to take the Presidency.

The main problem in America since Clinton’s election in 1992 is that the systemic rewards of being honest in government and academia have fallen at the same time that the consequences of being corrupt have.

That is, if you are an institutional Leftist in government/academia your rewards in being in the 99% are psychic ones as being a SJW lording it over the deplorables. While the other of institutional 1% pig out at the trough of corruption.

Donald Trump’s election as President denied the “99%” of the institutional Left’s it’s SJW psychic income while disrupting the cash flow of the 1%.

If Trump is re-elected after the Lefts attempted “Soft-coup”. Then I will be on the USA versus China in the long run.

Xi’s ascension to “Great-Leader for Life” is a sure fire way to see his life is short and China’s leadership succession after him a major crisis because of China’s corruption issues.

Gavin,

See also:

China’s Lethal Milk Scandal Reverberates a Decade Later

Bloomberg News

January 21, 2019

https://www.bloomberg.com/news/articles/2019-01-21/china-s-lethal-milk-scandal-reverberates-a-decade-later

“The deadly milk scandal of 2008 was a watershed moment for China’s consumers. Some 300,000 children were poisoned after Chinese suppliers added melamine, a chemical used to make plastic, to powdered milk to artificially boost protein levels. Tuesday marks the 10th anniversary of the sentencing to death in China of those at the center of the contamination and its concealment.

The scandal fueled a new era of consumer suspicion and China’s $27 billion infant-formula industry was reshaped to the near-exclusion of homegrown companies among the market leaders.

While Chinese government regulations on milk powder production are in line with international standards, consumers like Chen Jijie, a Beijing-based mother of two, will neither forgive nor forget.

“I won’t even consider giving domestic brands a chance, even 10 years later,” said Chen, who has a two-year-old child and a newborn baby. “The incident brought my confidence in Chinese baby formula brands to the lowest level.””

Grurray Said –

>>A few years ago they closed the last coal plant within the city limits. It was built in the 20s on the South Side. They closed it in the name of environmental justice.

>>The plan is to turn it into a distribution center for Amazon or Fed Ex. A lot of good that will do if the transmission towers outside of town are toppled and the power lines cut.

One of the big profitable side lines of American industrial plants since the late 1970’s has been the use of Combined Heat & Power (CHP) systems, AKA co-generation, to generate surplus electrical power to feed to the grid.

See:

https://en.wikipedia.org/wiki/Cogeneration#Cogeneration_in_the_United_States

Two issues arise here in terms of a US Red-Blue, Urban versus Rural civil conflict.

First, since NAFTA, many of the Blue area co-generating industrial facilities have been closed due to Chinese competition.

Second, EPA hazmat site laws, rules and regulations make it impossible to re-use “Brownfield” industrial sites in “Blue areas” for new heavy industrial plants because of the assumption of “Deep pockets” HAZMAT liability. This pushes all new American industrial development into “Green fields” sites in exurban to rural areas.

This EPA regulatory “Catch-22” — that increases industrial pollution to pristine un-polluted land — was a huge factor in the Pres. George W. Bush victory in Ohio in 2004, because of all the industrial development North of Cincinnati, South of Cleveland and around Dayton from the Iraq War defense spending.

I got to see this up close and personal via an armored glass site visit during the 2004 “MRAP Panic.” When the Bush Administration threw billions at up-armoring US Army vehicles of all sorts. The trucks I inspected at Sealy, Texas included. My job there was as a pre-award industrial capability site survey to a glass armor plant in the exurbs north of Cincinnati.

The Bush-Rove re-election team were aiming the US Defense Budget supplemental appropriations of fiscal years 2001, 2002, 2003, 2004, and 2005 like a laser at Ohio and other key Midwestern states to buffer the industrial losses from NAFTA.

When the Democrats took over the Congress in 2006. These Defense budget supplemental appropriations ended and the economic 2007 crisis arrived immediately afterwards to kill the Midwest’s economy, which then voted Obama twice there after.

Funny that.

In any case, as far as future American electrical co-generation, between Pres. Trump pulling the same defense spending tricks as Pres. Bush with defense spending and his tariffs on foreign made steel and aluminium. You are going to see the vast majority of America’s new co-generating industrial plants locate in “Red” areas with a heavy focus in the Midwest.

The sole exception to these industrial co-generation trends will be Illinois, as the corruption, tax and regulatory issues arising from Chicago’s control of the state capitol is driving out existing businesses and preventing new ones from relocating there.

Pres. Trump’s “Cold Civil War’s” economic front is aimed at shifting economic growth and the associated middle/working class family formation to Red areas and electrical power generation is following.

The Left, having seen this movie before, is trying to move the entire populations of Guatemala and El Salvador to the USA before the next census to counter that, and maybe prevent a 2nd Trump Administration.

One small plus of “mov(ing) the entire populations of Guatemala and El Salvador to the USA” is that these populAtions are probably better educated and more literate then the Mexican Indians we have been getting from southern Mexico who do not even speak Spanish, let alone English.

My housekeeper for years was a Salvadorian woman who had been legalized in 1986 by Simpson Mazoli. She was a hard worker who lived in a mobile home in Santa Ana. She told me she was going to move to Tijuana after she quit working as houses were cheaper. She planned to buy one.

“… U.S. Consumer Product Safety Commission, … The volume of consumer goods from China has nearly tripled since 1997, but the agency’s budget has increased just 12%, to $62 million, over the past five years.”

So much could be said, but that quote from Extreme Left ‘Time’ magazine encapsulates a lot: the implied answer to the problem of potentially defective Chinese-made goods is to hire more government bureaucrats to throw sand in the gears, not to move production back to the US where it would create jobs for American workers and tax revenues for bankrupt Federal, State, and local governments.

Corruption is indeed a problem, for China and for the US. In the US, we let our politicians pass laws to define what corruption is — and so a lot of Political Class behavior which is certainly immoral gets defined as legal. Just think about the Harry Reid Effect, where a poor man elected to Congress leaves as a multi-millionaire; but no corruption, of course. In China, sometimes they take a few corrupt officials down to the local soccer fields and shoot them — although I suspect that has more to do with Party in-fighting; the perpetrators were guilty of the wrong kind of corruption.

Today’s Extreme Left academics have destroyed in a few decades a university system which took centuries to build. We are surrounded by junk science — of which the Anthropogenic Global Warming scam is only the most egregious example. There are real problems, but we should be careful about accepting at face value claims about the dangers posed by certain chemicals in low concentration. Science and scientists have been corrupted by government funding, just as President Eisenhower warned in his famous Farewell Address.

I fear that the bottom line is that, while every country has problems of various kinds, the governing classes in China (and Russia) recognize the importance of looking out for the best interests of their countries; the governing class in the US is concerned only about virtue signaling for their peers and the short-term economic interests of a small number of rich Democrats. The best response to the growth of China would be to start fixing the damaging problems we have allowed to grow at home. But I can’t see an effective way to accomplish that goal.

Mike K,

There are 20,000 illegal immigrants a day showing up on our southern borders.

In slightly over 13 months 1 in 5 El Salvadorans and Guatemalans will be inside the borders of the USA.

President Trump’s threat to close the border is so that ICE can remove it’s port of entry work force to process the border crosser’s we have had to date and to try an stop the wilderness crossers elsewhere.

Basically, Pres Trump is threatening to tube the Mexican economy if the Mexican government doesn’t act to stop this migration.

I am also looking for Pres Trump to cut off the George Soros backed international NGO’s facilitating this mass migration from access to the American banking system before re-opening the US-Mexico border.

Gavin,

Regards the following —

I fear that the bottom line is that, while every country has problems of various kinds, the governing classes in China (and Russia) recognize the importance of looking out for the best interests of their countries; the governing class in the US is concerned only about virtue signaling for their peers and the short-term economic interests of a small number of rich Democrats. The best response to the growth of China would be to start fixing the damaging problems we have allowed to grow at home. But I can’t see an effective way to accomplish that goal.

I see you did not read the bloomberg.com article.

The CCP let 100,000 babies get poisoned baby formula.

Despite everything the CCP did afterwards, China lost nine of its top ten infant formula firms and the tenth only survived in the medium sized Chinese cities market because it because it was named American Dairy Inc in 2008.

Nestle SA is the biggest infant formula firm in China now.

After “American Dairy Inc” was forced to have a Chinese name, Feihe, by the CCP. It’s advertising is based on using foreign dairy sources (not subject to Chinese tariff’s). And it’s still losing to Nestle SA despite having a product that costs 1/2 as much.

Such is the price of Chinese Communist Party corruption.

Trent, I’m certainly not in favor of immigration, even legal immigration under the H1 B visa program, which is replacing skilled American workers with indentured servants,.

However, Salvadorian illegals are a better class than the recent Mexican immigrants who were from really primitive villages that do not speak Spanish.

I spent ten years reviewing California workers comp applications., beginning about 15 or 20 years ago. I would estimate 1/3 were illegals. Of those, most alleged a second grade education in Mexico. That was what they claimed ! Most were illiterate in Spanish, let alone English.

A sailing friend who worked for SCIF, the state workers comp carrier, told me that many of those illegals were in very dangerous jobs, like working as roofers with zero safety equipment.

He was a claims adjuster and saw the consequences.

I agree with shutting down the NGOs and Soros funded immigration organizations. I really have trouble understanding the motives of these organizers.

I’m reading Dreadnought again after 20 years. I’m on a WWI kick. In the book Massie points out that in the 1880s, Germany went on a colonies quest and ended up with a lot of territory but no Germans were interested in emigrating to the colonies. They all went to Wisconsin and Minnesota. Lots of German emigration but not to colonies.

My uncle told me that in the years before WWI, Chicago public schools had portraits of the Kaiser. He really has the heaviest responsibility for the War,

“The CCP let 100,000 babies get poisoned baby formula. ”¦ Such is the price of Chinese Communist Party corruption.”