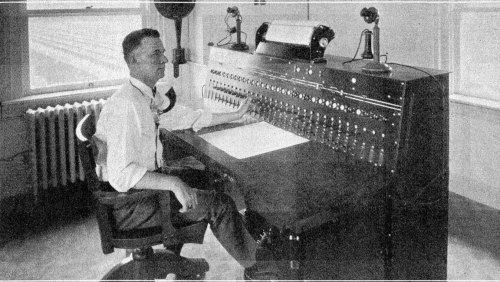

Ninety years ago this month, the first Centralized Traffic Control system was placed in operation, on a 40-mile stretch of railroad belonging to the New York Central. From a central console, the Dispatcher was able to control switches and signals anywhere in the territory. The positions of individual trains were displayed via lights on the panel. Interlocking logic at the remote locations ensure that neither dispatcher errors nor communication problems could set up potentially-dangerous conflicts.

In today’s terminology, it was a geographically-distributed robotics system, with a strong flavor of what is now being called the Internet of Things–although the communications links in the system were not provided by the Internet, obviously, the concept of devices announcing their status via telecommunications and receiving commands the same way was quite similar.

To railroad men of the time, the new system seemed almost magical:

The dispatcher was there and he was just filled up with enthusiasm on this new gadget called centralized traffic control… Along about 10 o’clock, he just yelled right out loud, ‘Here comes a non-stop meet.’ We all gathered around the machine and watched the lights that you know all about, watched the lights come towards each other and pass each other without stopping. That, to me… was history on American railroads, the first non-stop meet on single track without train orders… and you never saw such enthusiasm in your life as was in the minds and hearts of that crew.

CTC technology caught on quickly, and by the mid-1930s, stretches of track up to 100 miles long were regularly being operated under CTC control. In principal, there was no limit to how far away the operator could be from the controlled railroad territory.

I post items like this because they provide needed perspective in our present “age of automation” when there is so much media focus of robotics, artificial intelligence, and ‘the Internet of Things,’ but not a whole lot of understanding for how these fit on the historical technology growth trajectory.

Great post. My skepticism on IoT and robotics isn’t centered around potential job losses.

Imagine that CTC network running on a single party line telephone, those railroad men would have laughed you out of the building. Computer networking, especially secure computer networking is a difficult problem. That is why I have a decent paying job. IoT devices have really poor security and almost all of the require a subscription from the manufacturer to operate… I love gadgets and technology, but I will not purchase any IoT device that requires a subscription. Just a couple of years ago a botched Nest firmware update bricked a lot of people’s thermostats… Leaving them with no HVAC, which in most of the country can be a life threatening situation.

I am excited for the future of industrial and especially farm automation. That should put a damper on the Democrat’s voter import drive.

Uhuru,

–Ed

One of the railroads…I believe it is Norfolk Southern but am not sure…has enabled read-only access to its CTC system for home computers of certain key employees….they can view the status of the network, but cannot change anything.

It would be ‘interesting’ if the system that provides the one-way gate were breached by a hostile party. I don’t think accidents would occur, given that ultimate control lies with the interlocking logic out in the field, but evil people could certainly get things into a god-awful snarl.

To me the main concerns with automation are security (i.e., anything that touches the internet can be controlled by others, and I don’t want my thermostat, toaster, etc., controllable by anyone but me) and surveillance (i.e., I don’t want my thermostat, toaster, etc., reporting on me to anyone else, and I realize that modern computational capabilities mean that it requires no effort for bad actors to spy on me–this isn’t like East Germany anymore where it required an actual person to do the spying–it is trivial to spy on entire populations.).

Got t-boned in Baltimore last weekend and am looking for a new vehicle. Have decided to get oldest lowest mileage car I can to minimize interaction with IOT. When I turn the key, I want the engine to turn over. And I don’t want to know that some electronic part will fail in 3 years and I’ll have to replace an entire board on which half the components are obsolete. Give me metal parts not plastic.

if you’re interested in automation just consider Watt’s steam engine governor. The first analysis of automatic controllers was done by Clerk Maxwell. This is not new stuff, though like much else it advanced noticeably in The War.

About 8 years ago, the refrigerator in a house I had in Tucson died. There was spoiled meat in the freezer and it was a mess.

I did not realize that the refrigerator was operated by a motherboard that cost a thousand dollars to replace.

I replaced it and three months later, it failed again.

Another smelly mess as I was not living in the house but used it as a second home.

I had had no idea that a refrigerator had a mother board.

Most practical application for ‘IOT’ in the home, I think, is failure warning and prediction. It would be nice to be informed that your basement sump pump is on its last legs, or that the refrigerator has failed.

It would make sense to have a common household gateway, and the various devices communicate with that box…which should have proper security…rather than directly with the Internet on their own.

The home security providers (ADT, etc) would seem well-positioned for this if they can get their acts together.

Mike,

All refrigerators made since at least the 1990’s have motherboards. They are also not built to last. I have a 1978 Whirlpool fridge that is still going and I refuse to part with it. I have put new seals on both doors recently and only the icemaker is not working. Also, the active components, compressor, motor, are built cheaply and will fail in no more than a decade plus or minus 3 to 4 years. We had a 1993 GE fridge that failed in 2013. The repairman we called in said it would cost almost as much to repair and he cold not guarantee the replacement parts would not fail. We ended up buying a new one. The salescritters at Best Buy, Sears, and HH Gregg all kept trying to get us to buy fridges that had internet connections complete with 6″ touchscreens and buggy software. I refused. The new one still has a motherboard in it, but every new appliance does, including dishwashers.

I had ADT with that house and nowhere was there any discussion about monitoring.

The monitoring was by a friend who lived nearby and who checked the house once a week or so and who smelled the rotten meat,

Mrs. Davis, 1995 was the last year a carbureted car was sold in the US. Since then every car has had a computer. My experience has been that mechanical things break before electronic things in the cars that I’ve owned, or electronic things that interact with mechanical things like oxygen sensors. I’ve never had a main board go out on a car.

I was recently shopping for a washing machine. Similar issues. I noticed a Speed Queen (commercial?) model with high ratings on Amazon. Many of the comments mentioned favorably the machine’s relative lack of electronics and lack of mandatory water-saving programming. However, it was also expensive as compared to most of the alternatives. I ended up having our old washer repaired but doing so was possible only because I lucked into a competent appliance repair guy. He is so unreliable that I have since given up on him. This seems to be the tradeoff nowadays.

“I had ADT with that house and nowhere was there any discussion about monitoring”

AFAIK, they don’t sell such a solution now, but if they’re smart they will. They already support Internet connectivity for people who want video monitoring and/or remote turning on and off of the alarm system. Publish a standard protocol for any company who wants to provide a household IOT system to communicate with their gateway and thence indirectly with that company’s servers.

Roader,

Maybe now, but back in the mid 1980’s Ford started using a computer on all fuel injected vehicles. My Ranger had an 8086 chip in it controlling all engine functions. It was located in the engine compartment and in the Texas summer heat it burned out three times. It was rather disconcerting the first time it went out, as I was driving at 55 mph on a curved road. The engine suddenly quit, and I had no power steering and no power. I managed to get it off the road safely. The engine would not even turn over. It was a 10 minute walk to the shop of the mechanic I used, and he diagnosed the problem before he looked at it. This was in 1989 and it cost me $200 to replace the processor chip, 6 months after the warranty had run out.

Joe, putting the processor in the engine compartment was a pretty stupid thing for Ford to do. My injected ’88 F-250 had the computer in the cab, next to the driver’s left foot. I don’t know of any car today that doesn’t have the ECM in the interior of the vehicle.

Back when cars had carburetors it was unusual for them to last 200K miles. Even ’80s era Hondas and Toyotas had a hard time making that kind of mileage because the analog controls on the carburetors were so complicated and prone to failure. For instance:

Run away screaming: 1985 Honda CVCC vacuum hose routing diagram